Section Sewn Binding v Perfect Binding

Although they are not so obvious to see at first glimpse, these are 2 completely different methods of holding pages together in a book. If you are thinking about printing a book you need to consider your options and the effects of each option on the look, feel and longevity of your book.

To all intents and purposes a perfect bound book and a section sewn book look the same. They both create a spine that can be printed so that it can be seen on a bookshelf and they can be both used to create multiple book thicknesses from about 32 pages up to hundreds and even thousands of pages. Although we are not specifically talking hardback or softback in this article, you can use both these methods to bind the pages into a hardback or a softback book.

What is Perfect Binding?

A perfect bound book. Note the straight cut of the pages and the glue across the spine

Perfect binding was invented as a low cost way to bind books. Perfect bound books have strength limitations and their strength is affected by many things: how strong or flexible the glue is, what kind of paper and thickness of paper is used, the grain direction of the paper used and if the spine is likely to be forced flat by the reader. Perfect bound books are designed to spring shut and they should not be forced flat, this helps the perfect bound book to remain strong; as a result it is often difficult to open and read a perfect bound book with one hand unless the paper is very flexible and is able to be bent around the spine (like when reading a paperback novel). You will not be able to leave a perfect bound book open on a flat surface without breaking the spine or creasing the pages which both serve to destroy the strength and appearance of the book respectively. Perfect binding is most suited to books, novels and magazines with thin or lightweight paper which bends easily. It is also more suited to uncoated paper because the glue forms a stronger bond with paper fibres than it does with the coating on a silk or gloss coated art paper.

I’ve heard about PUR binding, and Burst Binding, are they the same thing?

Both PUR binding and burst binding are developments of Perfect binding.

Burst binding. You can see some complete folded sections and other sections where the guillotine has cut through the “notch” or the “burst” opening.

Burst bound sections showing the burst openings ready to be glued.

Burst binding (sometimes called notch binding) does not grind off the edge of the spine before gluing, like perfect binding does. The folded edge of the sections is “notched”, meaning a chunk of the section is removed allowing the glue to permeate through the notched hole into the centre of the folded section (or signature) which in gives a stronger bind than perfect binding, as long as the notches are created accurately.

Perfect binding glue (EVA) uses a holt melt glue and cures only as it cools. PUR binding uses a more advanced glue (polyurethane reactive) which continues curing by chemical reaction even after cooling, reaching full strength within 24 hours. Most agree PUR is at least 50% stronger than Perfect Binding. PUR binding is gradually replacing perfect binding and burst binding.

What is Section Sewing?

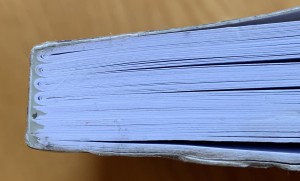

A close up of a section sewn book spine. You can clearly see the end of all the folded sections or signatures.

A section sewn book block before it has had the cover glued on

Section sewn or Smyth sewn or thread sewn is the Rolls Royce of binding. The page sections (signatures) are sewn together and then glued into the cover. The pages cannot be separated from the book without being ripped out. Not only does this create a long life archivable book, but it also lets the book open more easily and remain flat without being held open. This is very desirable for any kind of reference book, children’s book, cookery book or any prestigious book. The spine can also be forced flat to view the complete page right up to the spine – especially good for double page images – without any detrimental effects on the books strength.

When using heavier weight, coated papers, that do not bend easily, for example in a prestigious colour book, your printer should be recommending section sewing.

Is easy to see the difference between a section sewn book and a perfect bound book?

No, not at first glance. But if you look closely at the spine of a section sewn book you will see the edge of each folded section aligned side by side. To confirm that the book is section sewn, open the book at the middle of one of the folded sections and you will be able to see the thread holding the pages in place. Look closely at a perfect bound book and you will see all the page edges are cut in a straight line before being glued into the cover, so you can’t see a folded section. The remaining 3 edges are then trimmed to give a “perfect” finish (of course all binding methods are trimmed after binding in just the same way, but the name stuck with perfect binding!)

A close up of a perfect bound book spine

There are other binding alternatives for holding pages into a book which might be more suitable for you and have not been discussed in this article. Saddle stitching, side stabbing or wire-o-binding are some examples of these.

My advice to you would be to make sure you are talking to a printer that is able to offer both PUR binding and thread sewing so that you can openly discuss the benefits of each and decide which is best for your book.

Please feel free to contact me if you would like to discuss any of the above or suggest improvements to my blog.

David Exley david@beamreachuk.co.uk

Written by David Exley

David has an Honours Degree in Printing and Packaging Technology and has worked in both technical and sales roles in both the Paper and Printing industries for over 25 years.