To enable an image to be printed it must be broken up into a matrix of dots – called a halftone image. Traditionally the process of converting an original photograph into a halftone was done photographically with a halftone screen and the number of lines per inch (the resolution of the screen) was called the screen ruling. The higher the screen ruling, the higher the resolution, and therefore the smoother the image would be. However, as the screen ruling increases, so the image becomes more difficult to print, requiring digital screening, better plate making technology and higher and higher quality printing presses.

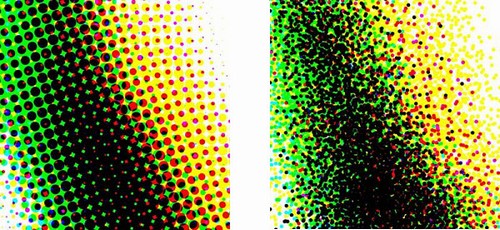

Today the vast majority of printers use a halftone screen ruling of up to 200 lpi (lines per inch) which is widely accepted as the best compromise of quality and economics of production. However there are still some limitations with this, which are particularly visible when reproducing patterned fabrics or fine lines and this is where FM screening (or stochastic screening) provides significant advantages.

Whereas the ink dots in halftones are equally spaced and variable in size, in FM screening, the dots are variably spaced, but equal in size, and this results in a much smoother image, more detail and the elimination of moiré patterning.

FM screening is not for everyone or every occasion, and it inevitably involves the printer in very tight control of their production variables. But it does create a printed wow factor, particularly when combined with stunning photography.

For more information or to discuss the possibilities for your project, please contact david@beamreachuk.co.uk.