Sewn Binding (also called section sewn, thread sewn or smyth sewn)

A book should last for life, not just for Christmas! Sorry for the joke, but we like to produce high quality books that last the test of time. If you’re thinking about producing a book and have spoken to a few printers, or done a bit of research on the internet, you will have worked out that most printers use a method called “perfect binding” to produce softback or hardback book. They might also talk about “PUR” or “burst binding” (these are essentially derivatives of perfect binding) and they all use only glue to create a non-flexible spine. However, there is a higher quality method of binding called “sewn binding”. At first glance a sewn bound book looks just like a perfect bound book, but from a functionality point of view, they are like chalk and cheese. So much so that, for some types of books, perfect binding is, in my opinion, not fit for purpose!

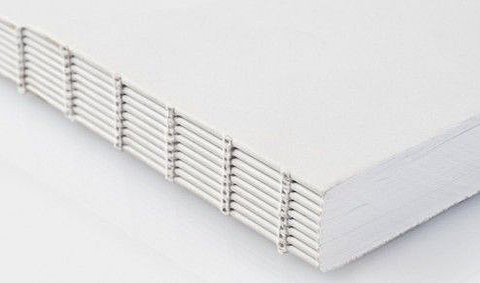

If you look closely at the cut edge of a sewn bound book you can see the collated sections.

What’s the problem with perfect bound books?

First of all you can get variable results with perfect binding. The page pull strength is affected by the type of glue, the amount of glue, the heat of the glue (holt melt), the amount of “ruffing up” of the cut edges of the paper just prior to applying the glue to the individual pre-cut pages. The pull strength of perfect binding is also affected by type of printing; Some digital presses use ink toners or oils which do not adhere to the glue, so some printers insist that printed areas should keep clear of the spine (no good for a photo book with double page spreads!). Also the page pull of a perfect bound book is seriously affected by the type of paper; uncoated paper adheres to the glue better than coated paper. Thinner paper adheres to the glue better than thicker paper. Thick paper also causes additional problems with perfect binding because it is less flexible, so when the book is opened, the books spine is more likely to be cracked open, or “broken”. If you get into the nitty gritty of paper manufacture, the paper actually binds better in one direction than the other as well!

Phew, what a minefield!! Can you imagine if your books get delivered and you are not happy with the perfect binding, the printer has all manner of excuses up his sleeve to wriggle his (or her) way out of a claim!

You are not supposed to break the spine of a perfect bound book. So, if your reader does happen to force the book flat in an attempt to make the book remain open without being touched, the books strength is compromised permanently. This is why a perfect bound book always wants to spring closed; its integrity depends upon the spine remaining unbroken. The glue is used to keep the book shut!! Not much good if you actually want to read it!

This hardback book contains a perfect bound book block!

What’s so good about sewn binding?

Sewn binding is sometimes called “section sewn”, “thread sewn” or “smyth sewn” after one of the original sewing machines. The pages are kept as folded sections so each page is permanently part of others within the book and then they are physically sewn together using thread. Each section (signature) is gathered together and the signatures are also sewn together to create a strong but flexible mesh within the spine. The spine is then glued into the cover, but using a more flexible adhesive than perfect binding. This means that not only will the pages never come out, but because the spine is more flexible, the book opens very easily, the spine can be forced flat, or “broken” without any loss of strength and the book will then lay open, or lay flat on its own. All high end books use this method of binding. This is also what we class as archive quality.

You can see the white thread in the spine and the whole area of the page is visible right up to the spine which is good for double page spreads. You can see that this book will lay flat without any loss of strength.

This is what the sewn book block looks like prior to having the flexible glue applied to case in the cover.

How much extra does sewn binding cost?

A rough guide:

Over 1000 copies: less than 5% extra

250 – 1000 copies: between 10-15% extra

Less than 250 copies: more than 20% extra

Why doesn’t my printer offer sewn binding at reasonable cost, or at all?

Maybe it’s because they don’t have the machinery, and possibly because they don’t have the experience of quality book production. Generally, only specialist high quality book printers have sewing machines, a lot of binding companies don’t even have them! So, remember, if you want to produce a quality book, it needs to be sewn and, if your printer doesn’t even mention sewn binding, I would question their ability to produce high end books.

What types of printed product is perfect binding good for?

Perfect binding is still good for some products, generally those with thinner paper, shorter shelf lives and where budgets are tight: magazines, novels, catalogues, prototype marketing samples, lined refill pads, installation manuals. Be warned, that any image that you print near to the spine may become invisible because the spine of perfect bound books and magazines is designed to stay unbroken.

What type of book is sewn binding good for:

Children’s books

Cookery books

Travel and guide books

Students study books

Non-fiction books

Any book which needs to have a shelf life over a year

Any landscape orientated book with a small spine length.

Journals / note books

Colourful books using high quality coated paper

Any hardback book. If you’re willing to pay for a premium hard cover, then sewn binding is a must.

FREE THREAD SEWN SAMPLE

Fill in your details and we will send you a free sample of a thread sewn book so you can see and feel the difference….